Sugatsune offers a wide range of leveling glides, from small-sized (M6) for small furniture and table-top analysers to very large-sized (Tr60) with a load capacity of 11 t for use in semiconductor equipment.

- Company Top

- About our Products

- Hardware Basics

- Leveling Glides

Leveling Glides Hardware Basics

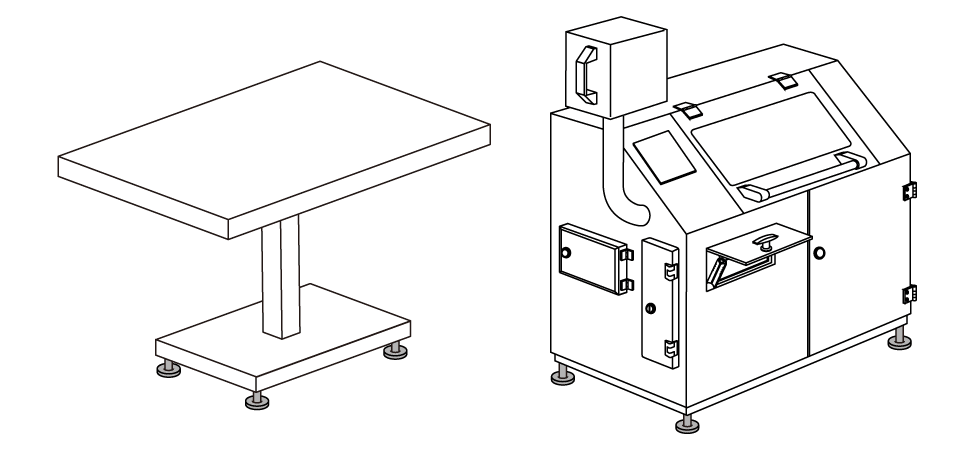

Leveling glides are used in various places, from tables, chairs, and box furniture to small analysers and large semiconductor equipment.

On this page, learn the basics about different types of leveling glides and how to choose them, including some unique options only available from Sugatsune.

Contents

What is a leveling glide?

Leveling glides are attached to the legs or bottom of furniture and equipment to adjust the height and keep them level (which prevents rattling).

Leveling glides are used to keep furniture and equipment level even when the floor is uneven or on an incline. Some products also have functions such as quake isolation.

Leveling glides may also be referred to as "adjustable glides".

Understanding Leveling Glide Load Capacity

①Vertical load

②Contact area

The load capacity of the leveling glide is described as 'load capacity N' or 'load capacity kgf' and represents the vertical load that can be withstood per leveling glide.

When attached to furniture or machinery, 'the load capacity per leveling glide' multiplied by 'the number of leveling glides used' (number of leveling glides properly grounded to the floor) will be 'the maximum load capacity'. Choose a leveling glide with appropriate load capacity. The load capacity must be more than the weight of the equipment and items on it.

How to Adjust the Height of a Leveling Glide

①Side panel ②Bottom panel ③Furniture base

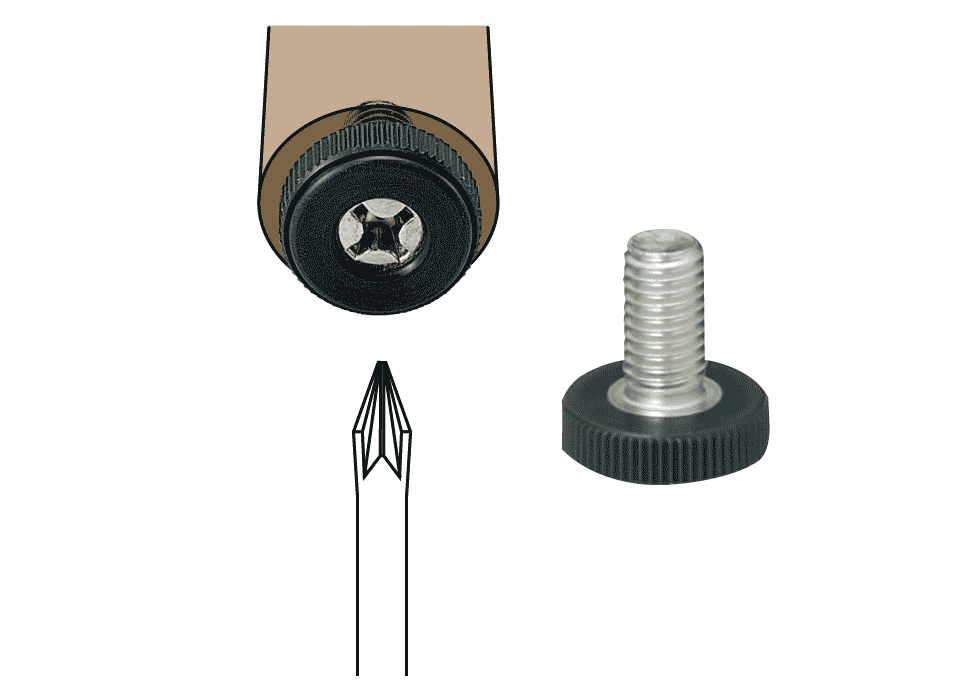

Method 1: Access Hole Adjustment

To adjust the height for this type of leveling glide, insert a Phillips screwdriver into a drilled hole in the bottom panel to access the top of the glide and turn to adjust.

With this long threaded bolt type of glide, you can conveniently adjust the height from the inside of the cabinet, even on furniture with a tall base.

The access holes can be covered with caps when not in use for a clean look.

Method 2: Screwdriver Adjustment

To adjust the height for this type of leveling glide, turn the the bottom of the glide with a Phillips screwdriver.

This type of leveling glide is used for lightweight furniture or equipment since the objects need to be manually lifted when making adjustments.

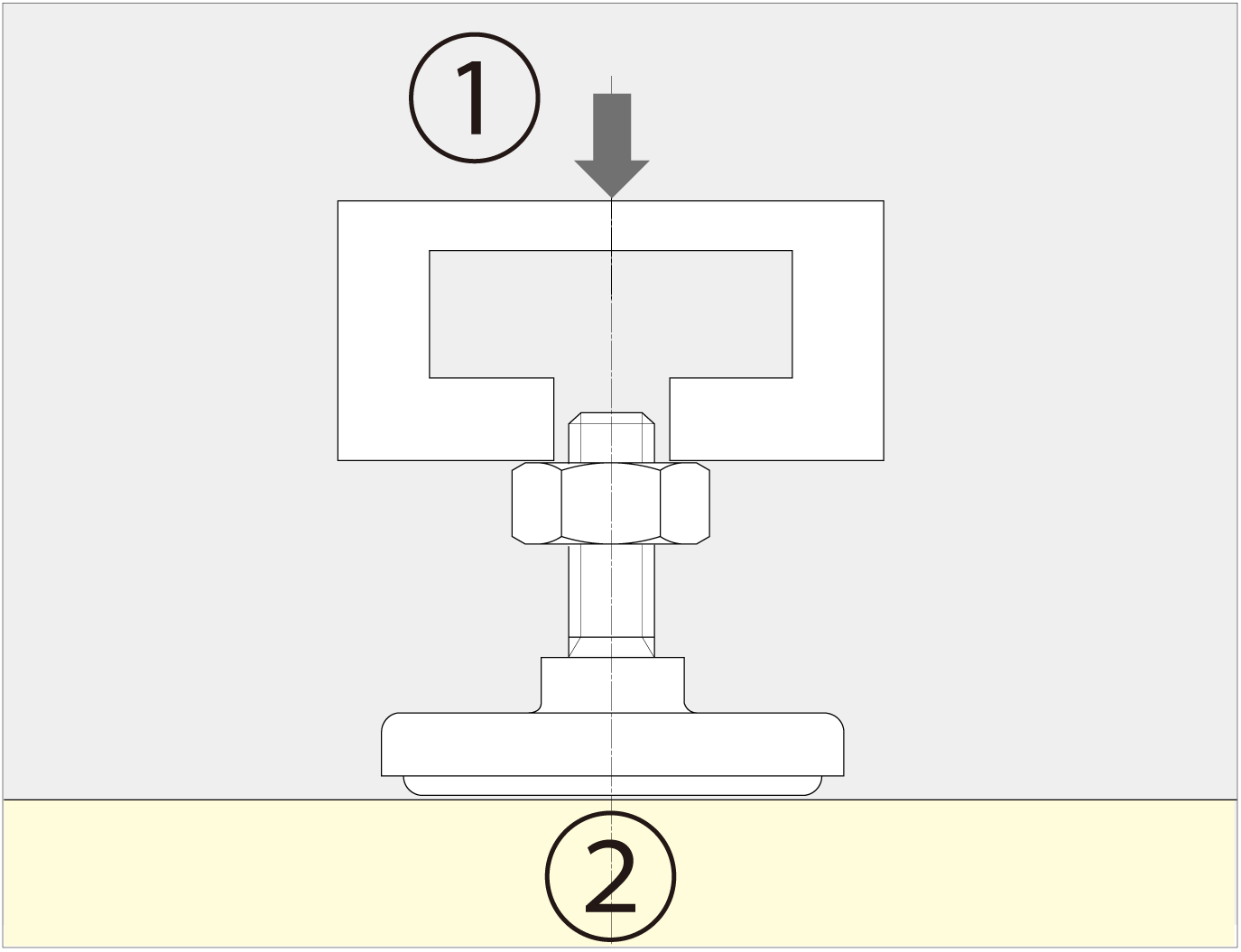

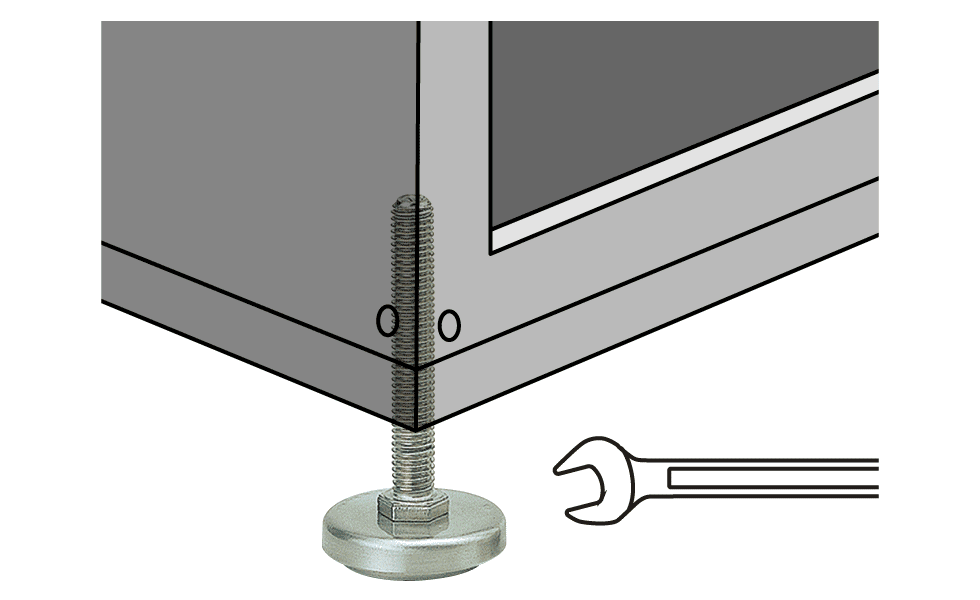

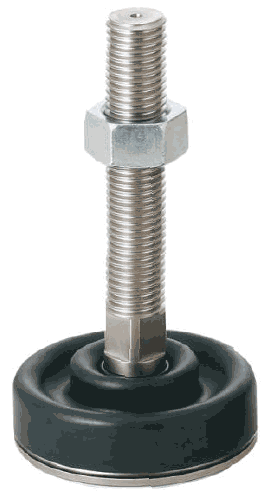

Method 3: Glide Nut Spanner Adjustment

This type of leveling glide has a nut integrated onto the threaded bolt. The height is adjusted by turning the nut with a spanner.

Adjustments can be made without lifting the equipment, but requires enough space to turn the spanner.

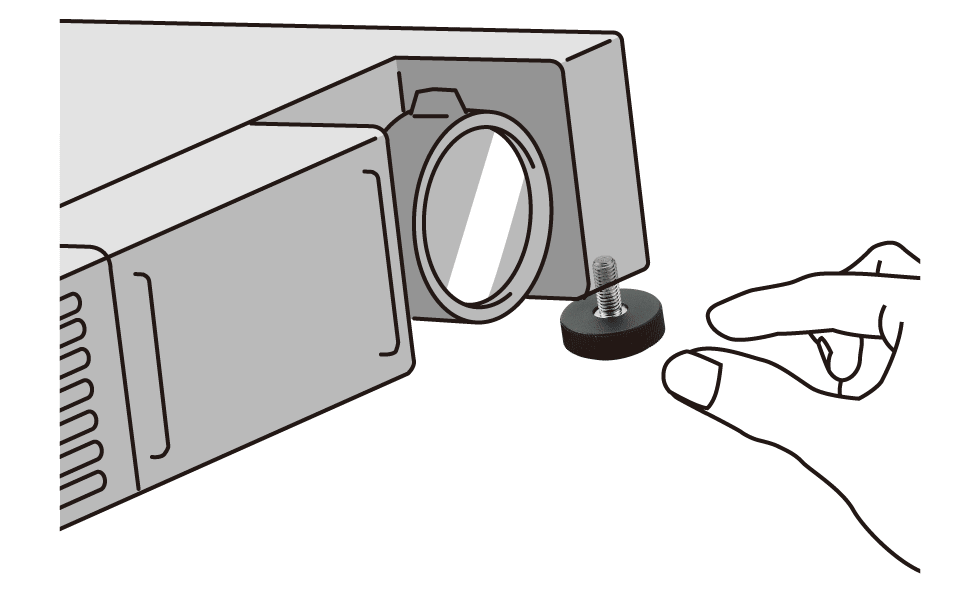

Method 4: Hand-Turn Adjustment

Adjust the height by turning the base of the leveling glide by hand.

The bottom part of the leveling glide features a dual structure, where only the upper section rotates when manually turned. This design allows for convenient adjustments without having to lift the furniture or device off the floor. Adjustments can be made easily without tools.

Types of Leveling Glides

Threaded Bolt and Base Materials

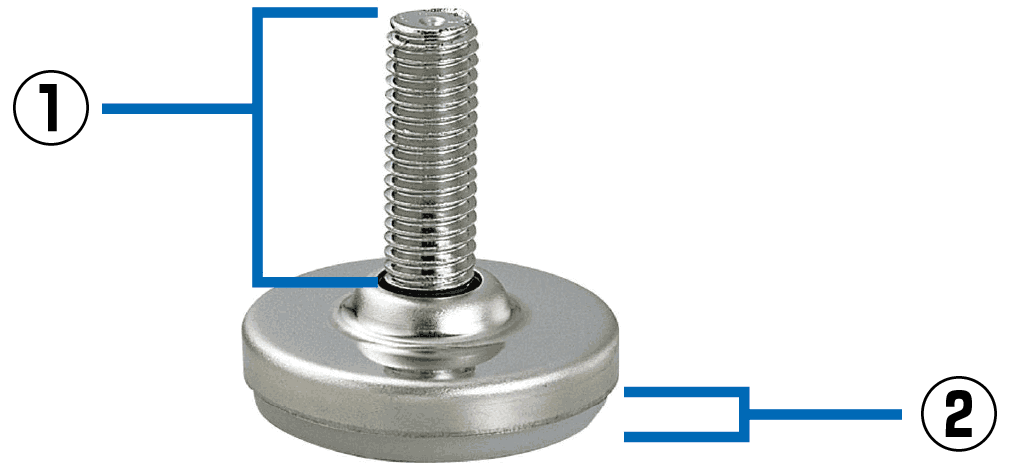

①Threaded bolt ②Base

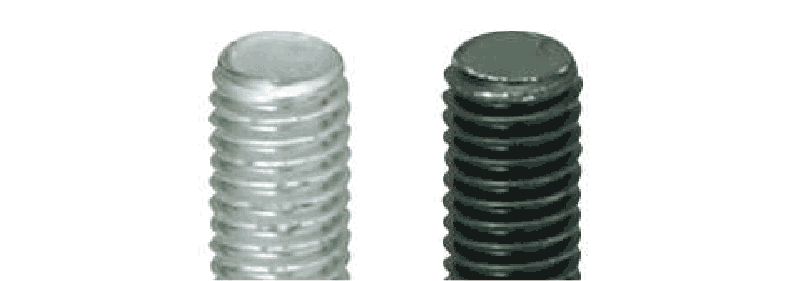

Threaded Bolt Materials

Stainless steel

Can be used in wet areas due to its excellent corrosion resistance and durability.

Steel

Less expensive than stainless steel. Available in a black finish.

Base Materials

Metal

Resistant to deformation and capable of handling high loads.

Resin

Reduced risk of floor damage compared to metal options.

Elastomer /

Ethylene Vinyl Acetate

Less prone to slipping compared to resin.

Additional Function(s)

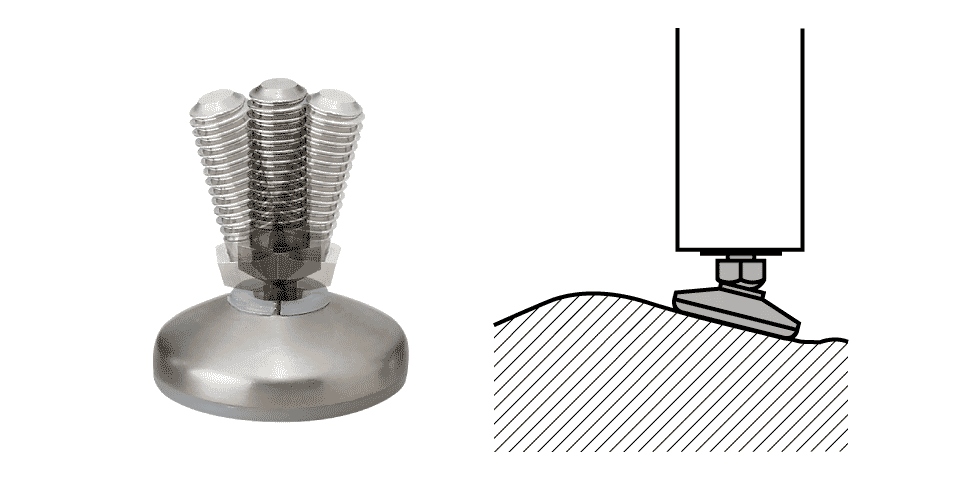

Swivel Function

The swivel function allows the bolt to swivel while the base stays in place.

Compensates for sloping or uneven floors. Can be attached to furniture and equipment with slanted legs.

*The swivel occurs in the connection part between the bottom and the bolt section.

Seismic Base Isolation

The base of the glide absorbs sway.

This type of glide can absorb shake by allowing the shaft to move while the base stays in place, unlike floor-fixed feet. This prevents equipment from falling over and causing damage.

Still

During small earthquakes

During big earthquakes

Self-Leveling

The self-leveling function automatically adjusts the level of tables on uneven floors with a special viscoelastic material.

It is ideal for tables which often need to be moved or rearranged.

Preventive Galling Treatment

A preventative galling treatment reduces friction on the threaded part of the bolt. This allows for smooth height adjustment.

Stainless steel has a low thermal conductivity and a high coefficient of thermal expansion, which can lead to the generation of frictional heat during nut tightening. The heat causes the screw to expand, resulting in the male and female threads sticking together and becoming immovable, a phenomenon referred to as "galling."

Related Product(s)

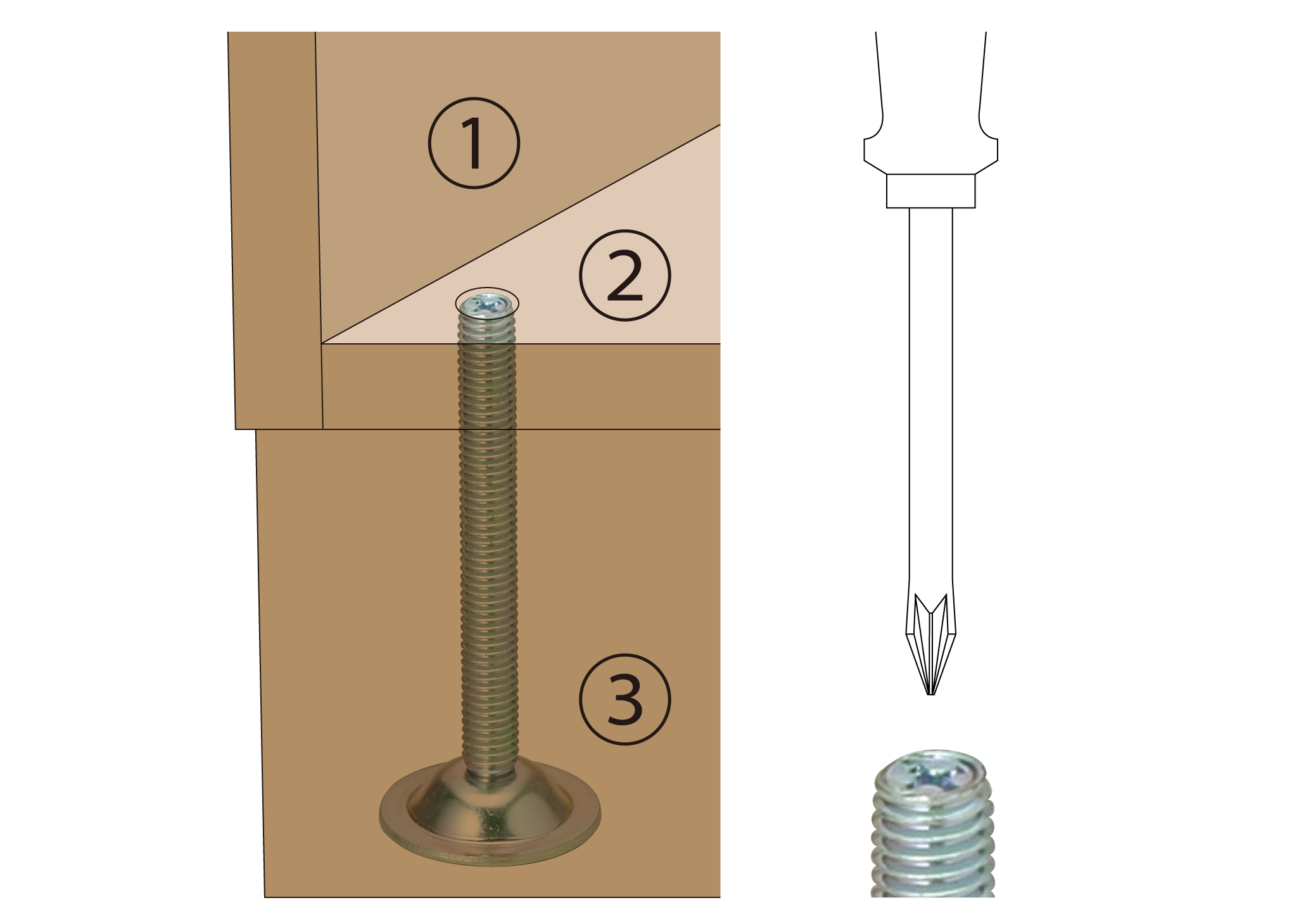

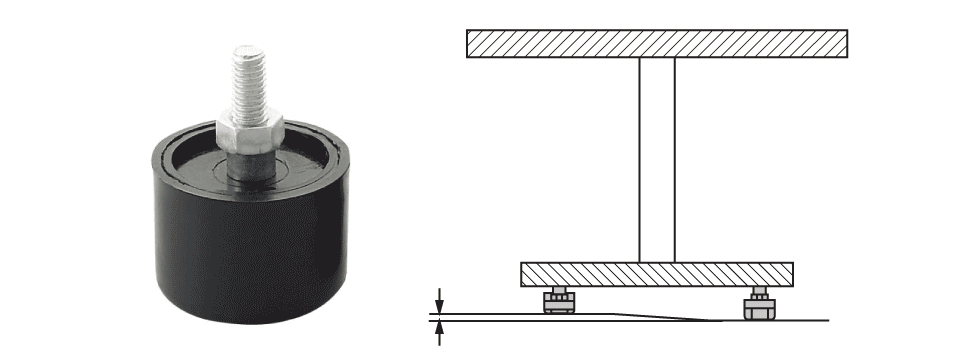

Glide Base

Glide bases make it easier to install leveling glides on wooden furniture. Screw or hammer-in installation types are available.

Select proper products based on the leveling glide bolt size.

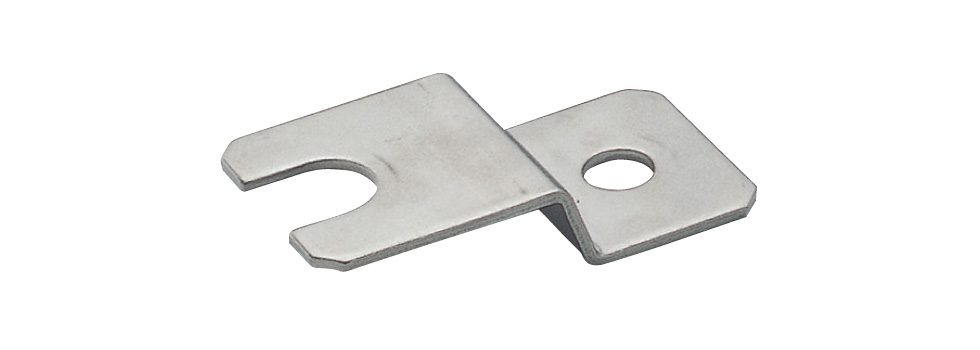

Washer for Leveling Glide

To easily secure the glide in place, insert the "C"-shaped part of the washer onto the hexagon nut on the leveling glide. Then, insert an anchor bolt through the hole in the washer and fasten it to the floor. Suitable for use with machine tools, conveyor belts, and other equipment that might experience vibration-induced movement.